Cleveland Clinic supply chief Downey describes industry changes and challenges

When Steve Downey joined Cleveland Clinic in 2021 as Chief Supply Chain and Patient Support Services Officer, he brought deep experience in leading teams dedicated to solving challenges and helping organizations fulfill their missions. An engineer by training, Downey found a career sweet spot in putting his technical and managerial expertise to work in service of medicine.

“I’ve always been passionate about healthcare,” Downey says. “I went to school and became an electrical engineer, specialized in biomed, and in my early days found a passion for the caregiving part through working on a project that had to do with neonates. I saw incredibly small babies, and yet here I was as an engineer, able to do something with devices to help those babies. That’s what I wanted to do. It’s always been about the patient.”

Downey spoke to Consult QD recently about the scope of healthcare supply chain management, current and future industry challenges and the importance of trust.

Advertisement

Cleveland Clinic is a non-profit academic medical center. Advertising on our site helps support our mission. We do not endorse non-Cleveland Clinic products or services. Policy

A: It starts with working with clinicians and non-clinical stakeholders to figure out exactly what they need. After that, it’s a matter of finding suppliers, writing contracts, doing diligence and getting the supplies to the right place. We need to make sure it’s all bought, accounted for and replenished in the right way.

We work in partnership with the clinical and non-clinical teams in the organization. Our sourcing scope ranges from clinical supplies like nursing and surgical items to non-clinical areas such as consultants, IT, construction and pharmacy.

Once we do the sourcing, the job is about making sure we deliver that material to the right place at the right time, yet not too much. Too little and it can impact patient care; too much and there’s no space for it or it will expire.

Our supply chain also works closely with other health systems through our Excelerate Group Purchasing Organization, or GPO. Excelerate allows organizations to leverage the clinical and supply chain expertise of Cleveland Clinic in their own organizations. As the leader of Excelerate, I focus on bringing the most possible value to those partner systems.

In addition to our Supply Chain team, I also manage the Patient Support Services team which encompasses the food and nutrition programs, Redcoats [patient guest services assistants], patient transporters and Service Express. A lot of what we do is embedded in day-to-day operations.

A: We want to support the clinicians by ensuring they’re working at the top of their licensure. If they have to hunt for a supply, it takes away time spent with the patient. And if there’s something that they need to make care better, like a new technology, then my team has to know about that technology and work with the clinicians to bring it into Cleveland Clinic. That includes new surgical solutions, the latest devices, robotics and AI.

Advertisement

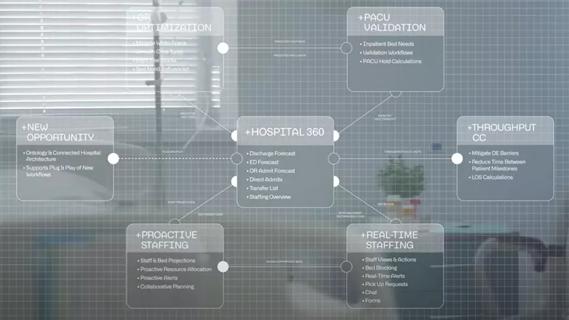

A: Technology allows us to have visibility. Last year, we implemented a best-in-class technology with Oracle Cloud that facilitates our procurement transactions. We combine that with Ivalua as a procurement platform. WaveMark®, our inventory management technology, tells us by RFID where everything is located. Our supply chain analytics team does key metrics and dashboarding. It’s also important to us to innovate, and supply chain has plenty of room for that. Currently, we have a group that’s working on drones and how we will move into drone delivery with supply chain.

A: Healthcare supply chain has never been easy, because there’s a lot of complexity in managing everything we do, but it has just gotten harder. There are a lot of difficulties in supply chain globally at the moment, with shortages and inflation.

On average, we used to have 30 items at a given time on backorder. Throughout 2021, that went up to 400 or more items. Our job then becomes mitigating that shortage impact while trying to keep pricing in control.

At one point, organizations went with a sole-source strategy. If you think of supply as a seesaw, with cost on one side and resiliency on the other side, the decision was made on the cost side of that seesaw. Now we’re trying to get balance. If our contrast agents are all made in one plant in Shanghai, is that good? Maybe it’s not. Maybe I need to dual source that, or maybe I need to keep more inventory on hand. We have to balance that seesaw while still driving toward an efficient enterprise.

Advertisement

One of the things our industry needs more of is trust. Automotive manufacturers know how many cars are being made. It’s very common to talk about production needs. The suppliers are an integral part of that equation and partner in production. It’s a collaborative approach. The same is true in retail. But in healthcare, the attitude has been “I’m not going to tell you.” And that’s not the best for everybody. We should share surgery schedules, forecasts and data, and bring everything together. If we do that, a vendor then says, “Steve, you’re going to run out in three weeks. What are we going to do?” rather than, “Hey, good luck.”

A: COVID shined a big spotlight on it, but drug shortages had been happening for much longer. A shortage of IV fluids bags took place in 2017, after Hurricane Maria hit Puerto Rico. That was a pre-COVID problem.

Supply chain has always been a really integral part of any operation, and the smart organizations knew that. Successful organizations have valued supply chain at the executive level, considering them a strategic asset. Now, since COVID, everybody from the board level on down is thinking about supply chain as a strategic asset, making sure it’s resourced and staffed and enabled. Cleveland Clinic has always valued supply chain. The leadership teams and the clinicians have always been supportive. It’s just that now we are very front-and-center in the conversation.

A: Resilience is one – factoring in how to be proactive so we can be resilient. It’s not enough to say “X happened, what should we do?” We need to be thinking, “X might happen, what will we do?” Resilience is a wellness program.

Advertisement

I think we have also learned creativity. Problems came at us from all over that we weren’t sure how to solve right away. We had to learn to think out of the box, and some of that has stayed with us. My mantra is that supply chain needs to be modern, agile, resilient and global. A lot of that derives from what happened with COVID.

A: Continued resiliency, inflation pressures and labor.

All of the financial challenges are huge for healthcare systems in general. We have to save more than we ever have, which means more alignment around products. It means more partnerships, it means more savings in a time of inflation.

It’s a challenge when you’re trying to make sure that product is on the shelf and the resilience, supply and labor challenges continue. We are making sure that we’re optimizing the workforce – that the staff is being used in the best way possible. These kinds of challenges will be with us through 2023 and beyond.

A: What I see at Cleveland Clinic absolutely supports the “team of teams” culture we hear about all the time. As challenges have arisen, the first response is “What can we do?” The group gets together and solves problems, and we are generally ahead of anybody else because we have a huge power in the “we.” That means that as a leader, you have a broad network. You work with all those people, and they trust you, they know who you are and that you are a resource.

I focus on Supply Chain as a service organization. We’re here to enable patient care. The team that responds well is built from people who are service oriented, and we try to bring joy in that service. That can be hard in these headwinds, but having a joyful approach helps. Who would you rather work with? Somebody who is not joyful or service oriented, or somebody who is bringing their energy and their joy to the work? We focus on that.

Advertisement

Advertisement

Advanced software streamlines charting, supports deeper patient connections

How holding simulations in clinical settings can improve workflow and identify latent operational threats

Interactive Zen Quest experience helps promote relaxing behaviors

Cleveland Clinic and IBM leaders share insights, concerns, optimism about impacts

Cleveland Clinic partners with Palantir to create logistical command center

A Q&A with organizational development researcher Gina Thoebes

Cleveland Clinic transformation leader led development of benchmarking tool with NAHQ

Raed Dweik, MD, on change management and the importance of communication